Lead Snake Construction Notes

Jump to navigation

Jump to search

Introduction

Materials

The Design

Construction notes

... back to the Applied Radiography home page

... back to the Wikiradiography home page

Introduction

Related Wikiradiography PagesThis page provides some notes for anyone contemplating construction of a lead snake. The original lead snakes were constructed in a basic home workshop. You will need good handyman skills and a well equipped workshop to make a lead snake at home.

Toolshttp://www.wikiradiography.com/page/Using+the+Lead+Snake+to+Reduce+Scatter+Radiation

Materials

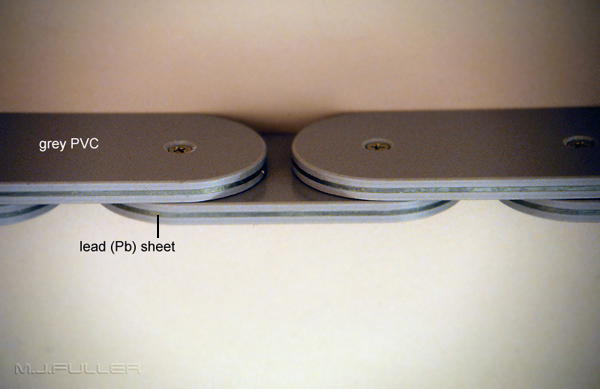

mdf sheet mdf was used to make template 3mm grey pvc sheet 1.3mm thick lead sheet 3mm countersunk head stainless steel bolts 3mm threaded sleevenuts these are used by carpenters contact cement and notched glue spreader flatbar mild steel used to make drilling guide

The Design

Construction notes

... back to the Applied Radiography home page

... back to the Wikiradiography home page