The printable version is no longer supported and may have rendering errors. Please update your browser bookmarks and please use the default browser print function instead.

|

A slip ring is electromechanical technology that enables the transmission of power and electrical signals from a stationary to a rotating structure. This transmission of power/data is made possible through electrical connections made by stationary brushes pressing against rotating circular conductors.

This technology is also called "rotary electrical joint" and "electric swivel" technology. A slip ring can be used in any electromechanical system that requires unrestrained, intermittent or continuous rotation while transmitting power and / or data. In Radiology, Slip Ring technology is found in CT, MRI, high-resolution ultrasound and digital mammography systems. In additional to medical systems, Slip Rings are also found in Electro-Optic Systems, Helicopters, Propellers, Wind Turbines and some Vehicles.

CT Slip ring technology was introduced to enable helical (continuous rotating) scanning. Prior to the introduction of Slip Rings, only Axial scanning was possible (which had the need to stop / reverse direction of rotation, after no more than 700 degrees rotation due to the finite length of the attached cables.) Slip ring technology eliminated the need for cables and enabled the continuous rotation of the gantry components.

|

|

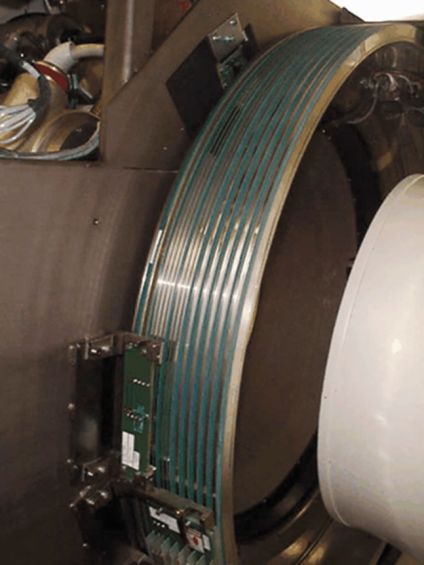

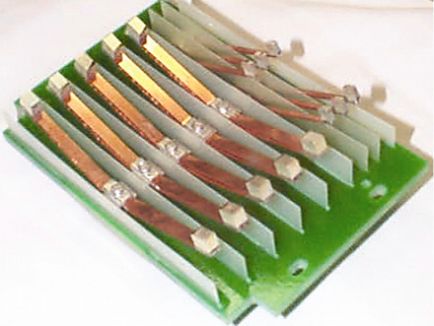

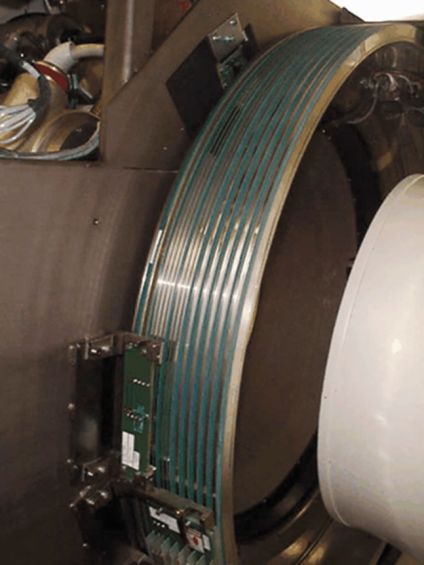

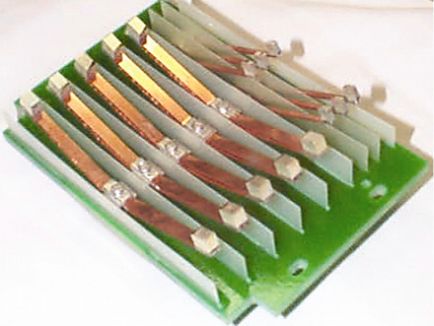

Slip rings used to bring power to x-ray tube on rotating gantry of a helical CT machine and, for some designs, to acquire information from the detector array. (a) The shiny metal strips carry electric signals that are swept off by special brushes. (b) The brushes are not in the form of bristles but rather of metal blocks (in this case a silver alloy). The five pairs of larger brushes provide the voltage required by the x-ray tube, and the three pairs of smaller ones transfer signals from the gantry controller. |